Behnam is a Computational Fluid Dynamics Engineer at ENA2. He received his PhD from the University of Calgary and was a postdoctoral research fellow at the University of Alberta before joining the team. His research involved coding, simulating, and analyzing fluid flow, as well as heat and mass transport in a variety of systems. His areas of focus included Newtonian/non-Newtonian fluid flows, flow in porous systems, reactive flows, particle-laden flows, and flow instability.

Predicting Cavitation in a Centrifugal Pump with CFD

The boiling temperature of a liquid has a direct relationship with the surrounding environmental pressure. As the pressure drops the liquid boils at lower temperature. You might have notices this if you are living in higher altitudes, where water boils at a temperature lower than 100℃. This is because as altitude rises, the pressure drops.

Boiling the water at a lower temperature than its normal boiling point is observed not only at high altitudes, but in very high fluid velocities as well. Because, according to the Bernoulli’s equation as the velocity increases, the pressure decreases. Then, water may start boiling at the room temperature if it has high velocities. This is not favorable in some industrial applications. For example, in centrifugal pumps water can start boiling if the impeller rotates with very high velocities. Consequently, the formation of bubbles and their collapse will damage the pump impeller. This phenomenon called cavitation is a very common reason for centrifugal pumps disfunction.

Predicting the regions and the working conditions in which cavitation may occur in a certain design is a common problem for pump manufacturers. Thanks to the advancement in the computational power of today’s computers. Computational Fluid Dynamic (CFD) is widely used to simulate the cavitation phenomenon to reduce the number of physical test in the design process.

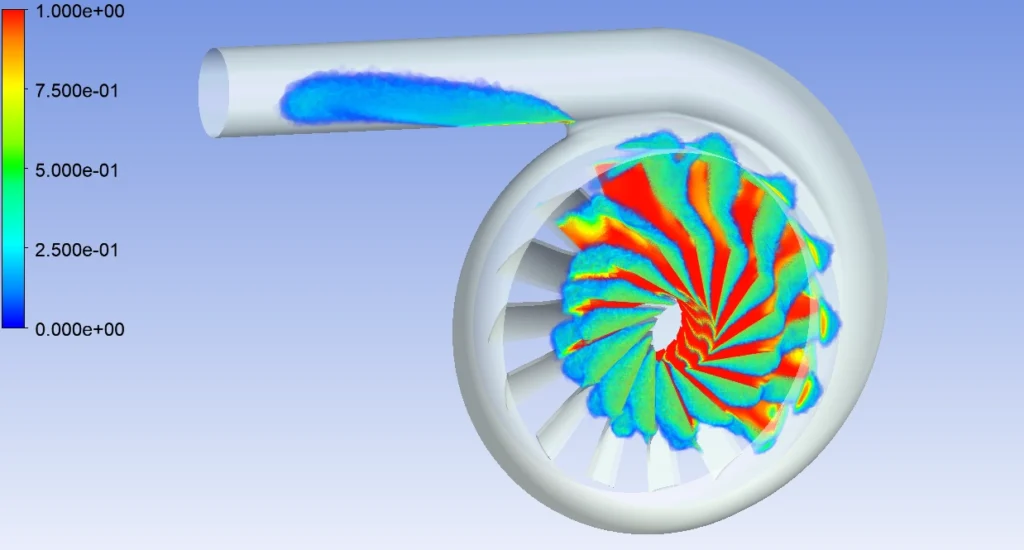

Fig.1 below shows the volume fraction of water vapor in a centrifugal pump whose impeller is rotating at 2000 rpm in the room temperature. It is observed that the bubbles are formed in the vicinity of the blades and their collapse will lead to the damage of the impeller in the long run.

To perform the CFD simulation, the mixture multiphase model is adopted to solve for the volume fraction of the water and water vapor. However, to resolve the liquid to gas phase transition, the so called SchnerrSauer model is used. For the current steady-state analysis, multiple reference frame analysis is adopted with the rotating reference frame defined for the fluid region that encloses the impeller. It is recommended to define the rotating fluid zone a little bit larger than the impeller itself. Finally, the K – 𝜔 SST model is used to treat the turbulence in the system with very high discretization scheme.