Behnam is a Computational Fluid Dynamics Engineer at ENA2. He received his PhD from the University of Calgary and was a postdoctoral research fellow at the University of Alberta before joining the team. His research involved coding, simulating, and analyzing fluid flow, as well as heat and mass transport in a variety of systems. His areas of focus included Newtonian/non-Newtonian fluid flows, flow in porous systems, reactive flows, particle-laden flows, and flow instability.

Learn How CFD Can Assist The Integrity For Valve Manufacturing

Computational Fluid Dynamic (CFD) utilizes numerical methods and data structures to analyze and solve problems that involve fluid flow, heat, and mass transfer. It is an alternative to reduce the number of physical tests in the design process and can be implemented early in the design for a quick assessment of design variations. It allows designers to examine any location in the region of interest and is more cost-effective than experiments to get essential engineering data. The team in ENA2 has deep knowledge of CFD and has performed projects for different industries.

One of the sectors that were interested in our CFD services is valve manufacturers. Valve manufacturers have to report the valve flow coefficient (![]() ) for their products. The valve flow coefficient is a valve’s capacity for a liquid or gas to flow through it and is defined as:

) for their products. The valve flow coefficient is a valve’s capacity for a liquid or gas to flow through it and is defined as:

Where, Q is the flow rate,![]() the pressure drop across the valve and SG is the specific gravity of the fluid. Specific gravity is a ratio of the density of the fluid to the density of the reference material:

the pressure drop across the valve and SG is the specific gravity of the fluid. Specific gravity is a ratio of the density of the fluid to the density of the reference material: ![]()

Usually, the reference material for liquids is water at 4ºc and for gases is air at 20ºc.

![]() is conventionally calculated by experiments. However, to save time and money we performed CFD analysis to calculate it. Practically, the volume flow rate of water

is conventionally calculated by experiments. However, to save time and money we performed CFD analysis to calculate it. Practically, the volume flow rate of water ![]() in US gallons/min with a pressure drop of

in US gallons/min with a pressure drop of ![]() across the valve is reported as

across the valve is reported as ![]() . Accordingly, the water flow though the valve is simulated with pressure boundary conditions of

. Accordingly, the water flow though the valve is simulated with pressure boundary conditions of ![]() and

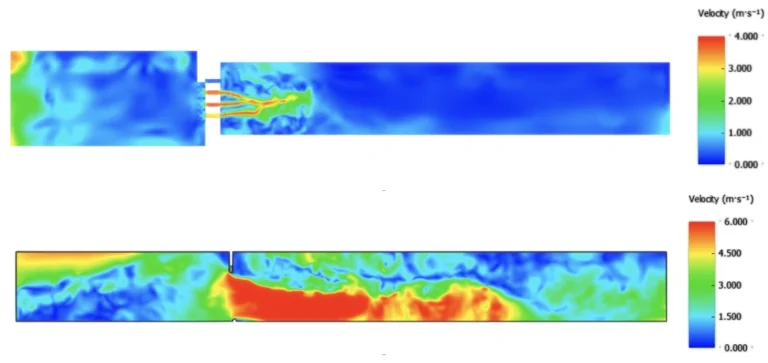

and ![]() and calculated the steady state flow rate in the domain. As mentioned, the calculated flow rated is US gallons/min is equal to the valve flow coefficient. The velocity contours in couple of valves are shown below.

and calculated the steady state flow rate in the domain. As mentioned, the calculated flow rated is US gallons/min is equal to the valve flow coefficient. The velocity contours in couple of valves are shown below.